Biosafety Level 3

Introduction

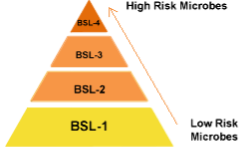

Biosafety level categorization is based on the threat of the pathogen contained in the laboratory, specifically the risk to the laboratory personnel, the environment, and the surrounding community. Laboratory biosafety levels are categorized by their inclusion of biosafety cabinets, air filtration, and other factors. Each level has specific controls for containment of microbes and biological agents (Figure 1). Biosafety level 3 (BSL-3) research laboratories are high containment spaces that conduct research on indigenous or exotic, life-threatening pathogens. BSL-3 pathogens pose a high threat to the environment, animals, personnel, and environment; therefore, the personal protective equipment (PPE) and procedural requirements for performing BSL-3 research are vast. BSL-3 research requires several types of precautions including laboratory practices, safety equipment, and specifications for facility construction. Laboratory practices include appropriate personnel medical surveillance and immunizations, training, as well as government clearance in some instances. Safety equipment includes appropriate PPE, respirators if applicable, and all work is conducted in biosafety cabinets.

Figure 1. Biosafety levels and the associated risk levels.

Sustainability in BSL-3 research spaces is dependent on approved standard operating procedures (SOPs) and behavioral changes of the personnel, much of which is determined by consultations with Biosafety Officers. Overall, there are SOPs in the BSL-3 that personnel must follow during their experiments, which can make reducing plastic and biohazardous waste very difficult. Unfortunately, BSL-3 laboratories require immense energy for constant directional airflow via HEPA filters, cold storage, and equipment. In addition, materials that enter the BSL-3 through the material transfer area cannot exit the BSL-3 without either being autoclaved or disposed of altogether. For example, all paper and single-use plastic materials that enter the BSL-3 area are immediately considered biohazardous, which renders recycling and waste reduction very difficult in those spaces. Below we have listed several current issues with sustainability in our BSL-3 spaces at CSU and potential opportunities for how we can enact long-term change. Of note, these potential opportunities are currently for discussion only as they have not been evaluated or approved and cannot be implemented until they are investigated by the CSU Biosafety Officers and included in approved SOPs.

PPE

Tyvek suites are used in BSL-3 spaces, dependent on the experiments being performed. For example, select agent and animal work often require both respirators and Tyvek suits. Respirators are sprayed with an appropriate disinfectant, wiped, allowed to sit for specified contact time dependent on the pathogen and disinfectant used, and then respirator hoods can be reused until the end of a research project or until broken/cracked.

Current recommendations are that Tyvek suits be disposed of at the end of any experiment, but this could potentially be modified to a more sustainable procedure by implementing the same methods used for respirators: disinfecting and reusing until the end of a research project or until the material is compromised. Thorough inspection of PPE with each use is already required for laboratory personnel working in BSL-3 to ensure that PPE is not compromised. Tyvek suits are $20 each, so this procedural change could be a cost-saving as well as a waste-reducing mechanism if personnel and environmental safety can be ensured.

The inclusion of biodegradable gloves is not recommended for these spaces, given the high pathogenicity of the biologicals used in research. However, biodegradable paper towels could be a safe and more sustainable practice worth implementing.

Paper Towels

Paper towels are used in high volume and can often only be used once before being autoclaved out of the BSL-3 for disposal. Switching to sustainably sourced and biodegradable paper towels is potentially an easy and cost-effective change to make in the lab. Friendly Green ‘the Big One’ Single-Ply Wipes are a cheaper and more environmentally friendly alternative. The wipes and boxes are made from 100% recycled cellulose and are biodegradable (https://us.vwr.com/store/product/23571235/friendly-green-the-big-one-single-ply-wipes-high-tech-conversions). Additionally, several companies like Tork offer a classic paper towel alternative made from 100% recycled materials that is compostable (https://us.vwr.com/store/product/7091373/tork-perforated-roll-towels).

Pipet tips

Pipet waste disposal in BSL-3 includes the deposition of pipet tips into a container with the proper ratio of disinfectant to waste materials. These containers (“boats”) are used and then disposed of via autoclaving immediately upon the completion of an experimental process. We propose three opportunities for sustainable practice regarding pipet boats: 1) the use of reusable pipet boats, 2) leaving the pipet boat in the BSC until it is full and then autoclaving, rather than at the end of each process, and 3) refilling pipet boxes.

Pipet boats and boxes are disposal containers for used pipet tips. These containers can be disposable, such as cardboard boxes, or reusable, such as autoclavable plastic. The plastic boats are a higher initial cost (approximately $50 per boat) but have a long lifespan, even considering regular utilization in the laboratory and repeated autoclaving (https://assets.fishersci.com/TFS-Assets/LCD/manuals/Nalgene-Instrument-Pipet-Sterilizing-Pan-EN-8-0401-69-1109.pdf).

Procedurally, the refillable pipet boxes could be implemented by the following:

- Using a pipet tip box until empty

- Disinfecting pipet tip boxes, wiping, and allowing to sit for disinfectant contact time (specified by Biosafety and dependent on the disinfectant used)

- Autoclaving the empty box out

- Refilling the box with filtered pipet tips outside of the BSL-3

- Autoclaving the box into the BSL-3 to sterilize the tips and using until depletion

Materials reduction

Personnel can minimize what they bring into the BSL-3 such as single-use plastics, media bottles, plastic wrappings, and Styrofoam that could otherwise be recycled or reused outside of the BSL-3 space. Reductions can be made in energy usage by turning off any machines that are not in immediate use or associated with safety needs, such as lights, water baths, computer monitors, etc. Another potential cost-effective and energy-saving procedure is switching ULT freezers from -80°C to -70°C, which can reduce energy usage by 30% without compromising sample integrity (https://www.mygreenlab.org/cold-storage.html).

Summary

Enacting change is very difficult and requires careful consideration when it comes to stringent biosafety requirements. However, taking the time to periodically assess protocols and procedures for opportunities for improvement in sustainability as well as current best practices is worthwhile. Some identified potential opportunities for evaluation specific to BSL-3 spaces include the following:

- Assess current SOPs and modify to include sustainability when appropriate (e.g. PPE, pipet tips and boats, paper towels, materials reduction).

- Require future SOPs to have sustainability efforts listed in the protocols.

- Require training for new personnel on sustainability efforts and best practices.

- Post signs in BSL-3 areas encouraging and explaining approved sustainability practices when possible.

Authors: Sarah Cooper, Shelby Cagle, and Sam Courtney