Fume Hoods

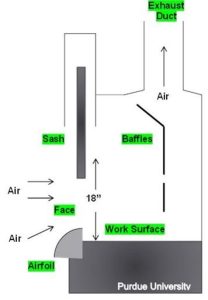

Fume hoods are an essential piece of laboratory equipment found in many research labs. In contrast to biosafety cabinets (BSCs), which are typically used for handling biological samples and are designed to protect both the researcher and the sample contained within the cabinet, fume hoods are generally used for handling chemicals and other materials that can generate hazardous gases or vapors and are designed to protect the researcher and others in the area. Fume hoods usually consist of an exhaust system, which creates directional airflow, pulling air from the room into the fume hood and through ducts that connect the hood and the building, eventually exhausting the air into the atmosphere. Through this process, any hazardous vapors or gases generated by work with chemicals are contained within the hood and exhausted outside the building, preventing those vapors from causing harm or risk to the researcher. Aside from an exhaust duct through which the air moves from the hood and a fan to move the air, fume hoods also generally consist of a sash, airfoil, face, and baffles. The sash is the glass window at the front of the hood that can open and close vertically or horizontally. The airfoil is likewise at the front of the hood and assists in directing airflow into the hood. The face of the hood is the opening through which air is drawn and changes as the hood sash is opened and closed. The ‘face velocity’ is the velocity of the air moving into the hood through the face or opening. The baffles are near the back of the hood and help direct airflow into the exhaust system. In order to allow a fume hood to operate properly and to allow the air to flow in the appropriate direction, fume hoods should not be used for storage of items. Rather, they should ideally be set up each time they are used. In addition, when using large equipment or items in the hood, they should be placed on a stand that is slightly elevated, to allow air to flow appropriately (Purdue University, n. d.).

Fume hoods are an essential piece of laboratory equipment found in many research labs. In contrast to biosafety cabinets (BSCs), which are typically used for handling biological samples and are designed to protect both the researcher and the sample contained within the cabinet, fume hoods are generally used for handling chemicals and other materials that can generate hazardous gases or vapors and are designed to protect the researcher and others in the area. Fume hoods usually consist of an exhaust system, which creates directional airflow, pulling air from the room into the fume hood and through ducts that connect the hood and the building, eventually exhausting the air into the atmosphere. Through this process, any hazardous vapors or gases generated by work with chemicals are contained within the hood and exhausted outside the building, preventing those vapors from causing harm or risk to the researcher. Aside from an exhaust duct through which the air moves from the hood and a fan to move the air, fume hoods also generally consist of a sash, airfoil, face, and baffles. The sash is the glass window at the front of the hood that can open and close vertically or horizontally. The airfoil is likewise at the front of the hood and assists in directing airflow into the hood. The face of the hood is the opening through which air is drawn and changes as the hood sash is opened and closed. The ‘face velocity’ is the velocity of the air moving into the hood through the face or opening. The baffles are near the back of the hood and help direct airflow into the exhaust system. In order to allow a fume hood to operate properly and to allow the air to flow in the appropriate direction, fume hoods should not be used for storage of items. Rather, they should ideally be set up each time they are used. In addition, when using large equipment or items in the hood, they should be placed on a stand that is slightly elevated, to allow air to flow appropriately (Purdue University, n. d.).

As with BSCs, there are many distinct types of fume hoods. Fume hoods fall into three basic categories: standard, bypass, and auxiliary. Standard fume hoods are constant air volume (CAV) hoods in which the amount of exhausted air is constant. This means that the sash height on these fume hoods affects the face velocity of the air entering the hood. As the sash height is lowered, the face velocity increases. This also means that as the sash is lowered there is not necessarily a reduction in the amount of energy used by the hood, since the amount of exhausted air remains constant. In contrast, there are also standard fume hoods with variable air volume (VAV) control. In these types of hoods, there is a valve or dampener that controls the volume of exhausted air as the sash height is changed, thereby maintaining the face velocity and preventing an increase in velocity as sash height is lowered. Bypass fume hoods contain a bypass area which directs airflow as the sash height is adjusted. For example, as the sash height is lowered, more air will flow through the bypass area, preventing a drastic increase in the face velocity. Auxiliary fume hoods are variations of the bypass fume hoods and contain an auxiliary air supply that supplies outside air into the hood. This type of hood carries the risk of directing vapors from the inside to the outside of the hood and is therefore generally not permitted at most institutions (Purdue University, n.d., Oregon State University, 2006). According to a September 2022 version of the Equipment Division of the CSU Facilities Planning, Design, and Construction Standards, standard or conventional fume hoods and auxiliary fume hoods are not acceptable due to the potential risks that can result from the increase in face velocity as the sash is closed, in the case of standard hoods, and from the extraction of vapors from within the hood, in the case of auxiliary hoods. CSU’s standards for construction also stipulate that low-flow, high performance fume hoods be installed in new research buildings (Colorado State University, 2022). It is therefore important to be aware of the types of fume hoods in use in your lab in order to ensure proper use and maintain mindfulness of how air flow is affected as sash height is changed.

Across CSU, there are around 850 fume hoods of varying types. CSU Environmental Health and Safety (EHS) maintains a fume hood database for all hoods located on campus. EHS also attaches a sticker/posting to each fume hood to ensure proper usage and researcher safety when working in fume hoods. All hoods are inspected and certified annually for air flow by EHS (March & Green). The EHS website contains helpful information for who to contact with questions about fume hood certification and safety, along with general guidelines and safety instructions for fume hood users.

While fume hoods are a vital component to most research labs, as evidenced by the large number of fume hoods in operation across a research-intensive university such as CSU, they come with a high energy and financial cost, which becomes important when considering how to implement sustainability into research settings. An individual fume hood uses approximately three-and-a-half homes worth of energy, which is far more than most other pieces of lab equipment. There are an estimated 500,000 to 1,500,000 fume hoods in use across the United States, totaling over $4 billion in operation costs (Mills & Sartor 2005).

In addition to proper set-up and use of fume hoods, another strategy to decrease the energy costs of fume hoods is to close the sash (when appropriate for the type of fume hood) each time a user is done working in a fume hood, which prevents fume hoods that are not in use from continually exhausting large volumes of air. This can not only save energy and money but can also improve safety since unattended items are not likely to be left in the hood if users are sure to clean up their work and close the sash when done.

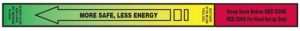

To encourage users to close the sash when done working in fume hoods, Harvard University initiated a “Shut the Sash Program” in 2005 in the Chemistry and Chemical Biology Department. This program posted stickers (such as the one depicted below) on fume hoods to remind users to close the sash and also encourage competition among labs to close the sashes on their fume hoods as often as possible when not in use. The impact of this program was evaluated, and it was reported that as of 2010, several years after initiating the program, the fume hood exhaust levels decreased by 30%, saving over $240,000 and reducing greenhouse gas emissions by over 300 metric tons. They also noted enthusiasm in the participating researchers to engage in the program and to see how their behavior changes around fume hood use led to a reduction in energy and financial cost as well as in negative environmental impact (Shut the Sash Program, 2021). Other institutions have implemented similar programs. For example, University of California Davis and University of California Santa Barbara posted stickers across their campuses, notifying users to shut the sash when done in the hood and found over $1,300 in savings per hood each year (Becerra et al., 2018). The positive impact of implementing a program to encourage shutting sashes on fume hoods is clear, and the “Shut the Sash” program has been implemented at CSU as well, spearheaded by Stacey Baumgarn, CSU’s Campus Energy Coordinator, and Anthony Appleton, CSU’s Research Safety Culture Program Coordinator.

By contacting Stacey or Anthony, you can receive a “Shut the Sash” sticker, such as the one shown above. The sticker helps to remind those in your lab to close the sash when done working in a fume hood, encouraging behavioral changes that can result in a reduction in energy use and greenhouse gas emissions, thereby introducing more sustainability into your research lab. In leading this program, Stacey has emphasized his desire to personally visit with the lab managers/PIs before and as the stickers are applied to the fume hoods to ensure that the “Shut the Sash” campaign is appropriate for the labs. Beyond simply applying a sticker, Stacey can then maintain accurate numbers of laboratories that participate in the campaign and discuss why it is important to engage in this and other sustainable behaviors. You can find more information online about the Green Labs program at CSU, which aims to educate about and encourage more environmentally friendly and sustainable behaviors in research labs, including the “Shut the Sash” campaign:

There are numerous ways, as depicted throughout this guide, to increase sustainability in your research practices. Participating in the “Shut the Sash” campaign is one highly impactful way to reduce energy consumption and greenhouse gas emissions, and it is a simple behavior in which all members of the lab can engage.

Authors: Kimberly Shelton and Deb Green

References:

- Becerra, L. L., Ferrua, J. A., Drake, M. J., Kumar, D., Anders, A. S., Wang, E. N., & Preston, D. J. (2018). Active fume hood sash height monitoring with audible feedback. Energy Reports, 4, 645–652. https://doi.org/10.1016/j.egyr.2018.09.010

- Colorado State University. (2022, September 6). Equipment. CSU Facilities Planning, Design, and Construction Standards. Retrieved October 20, 2022, from https://www.fm.colostate.edu/wp-dev/wp-content/uploads/standards/Part_III/III_Division_11-Equipment.pdf

- March, E., & Green, D. (2022, October 31). Fume Hoods. Personal.

- Mills, E., & Sartor, D. (2005). Energy use and savings potential for laboratory fume hoods. Energy, 30(10), 1859–1864. https://doi.org/10.1016/j.energy.2004.11.008

- Oregon State University. (2006, January 6). Fume Hood Types. Environmental Health and Safety. Retrieved October 19, 2022, from https://ehs.oregonstate.edu/LVSG-FH-type

- Purdue University. (n.d.). Chemical Fume Hoods. Radiological and Environmental Management. Retrieved November 10, 2022, from https://www.purdue.edu/ehps/rem/laboratory/equipment%20safety/Lab%20Safety%20Equipment/cfh.html#:~:text=The%20purpose%20of%20a%20chemical,hazardous%20and%2For%20odorous%20chemicals

- Shut the Sash Program. (2021, September 28). Sustainability at Harvard. https://green.harvard.edu/programs/green-labs/shut-