Preparing Plant Vitrification Solution 2

Katheryn Chen, Department of Soil and Crop Sciences, Colorado State University, 307 University Ave., Fort Collins, Colorado 80523.

Remi Bonnart, USDA-ARS National Laboratory for Genetic Resources Preservation, 1111 S. Mason St., Fort Collins, Colorado 80521.

Gayle M. Volk, USDA-ARS National Laboratory for Genetic Resources Preservation, 1111 S. Mason St., Fort Collins, Colorado 80521. Gayle.Volk@usda.gov

Outline

- Background

- Recipe

- Step-by-step instructions

- Variations

- References

- Additional information

- Acknowledgments

The PVS2 recipe is available to download here.

1. Background

Successful preservation of living plant tissue in liquid nitrogen (-196 oC) depends upon the ability to prevent damage to the cells. Ice crystallization that occurs during the freezing process, particularly the intracellular formation of large ice crystals, poses an acutely lethal threat. While a phase change from liquid to solid necessarily occurs during a transfer to extreme low temperatures, vitrification—the process by which liquids solidify into metastable glass—can preserve cellular integrity.

Vitrification techniques use cryoprotectants that osmotically desiccate the tissue without severely damaging it. Glycerol-based cryoprotectants, such as Plant Vitrification Solution 2 (PVS2; Sakai et al., 1990) and PVS3 (Nishizawa et al., 1993) benefit from glycerol’s high viscosity and ability to be supercooled below -70 oC.

PVS2 was developed by Dr. Akira Sakai in the 1980s to cryopreserve 1 mm apical meristems from plants grown in tissue culture. Dr. Sakai outlines his personal experience developing PVS2 in ‘Development of PVS-Based Vitrification and Encapsulation–Vitrification Protocols’ (Sakai et al., 2008). He first tested PVS2 on nucellar cells of navel oranges, which resulted an 80% survival after rapid rewarming (Sakai et al., 1990).

The development of PVS2 as a cryoprotectant, coupled with an osmoprotection treatment (loading solution) to prepare the tissues for dehydration, was a significant in the field of clonal plant cryopreservation. This critical technology has greatly expanded the utility of meristematic cryopreservation; since its development, it has been used and adapted to a wide-ranging, diverse taxa including a variety of tropical plants (Sakai et al., 2008).

2. Recipe

PVS2 Cryoprotectant Recipe (0.4 M sucrose + ½ MS): 250 mL

- Glycerol (30% w/v) = 75.0 g

- Ethylene glycol (15% w/v) = 37.5 g or 33.7 mL

- Sucrose (0.4 M) = 34.23 g

- Dimethyl sulfoxide (15% w/v) = 37.5 g or 34.1 mL

- Murashige & Skoog basal medium with vitamins (PhytoTech Labs M519) = 0.55 g

- Bring to volume with distilled water

- Adjust pH to 5.8 with potassium hydroxide

- Filter sterilize using syringe filter or Stericup units (0.45 microns or smaller)

3. Step-by-step instructions

This section describes to how make PVS2 at the USDA-ARS National Laboratory for Genetic Resources Preservation (NLGRP) in Fort Collins, Colorado. This formulation has been successfully used to cryopreserve meristematic tissue from a wide variety of clonal crops including mint, strawberry, potato, sweet potato, citrus, banana, grapes and more.

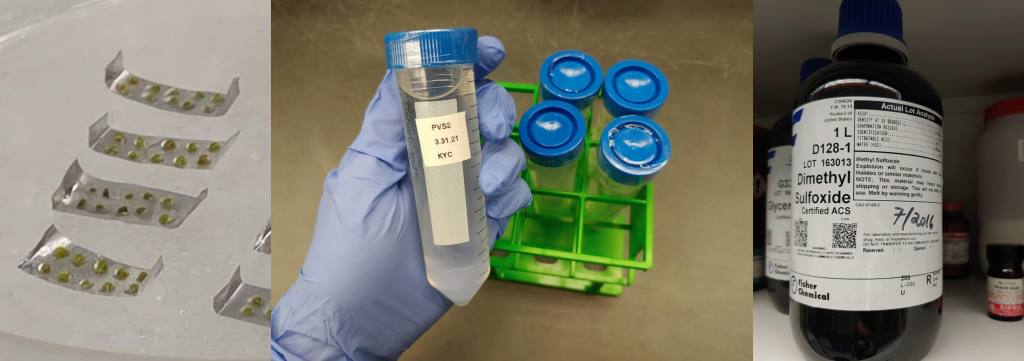

Video 1. Technician Katheryn Chen prepares 250 mL of PVS2.

In addition to the chemical ingredients, some standard laboratory equipment is needed to prepare PVS2. Beakers or flasks, graduated cylinders, stir bars, stir plates, pipettes, a pH meter, precision balances, filter sterilization units, centrifuge tubes or test tubes, and personal protective equipment are among the necessary equipment. Additionally, access to a laminar flow hood as well as an autoclave are needed to maintain sterile tools and working conditions.

Prior to preparing media, review all SDS and consider safety precautions needed for chemical handling, potential accidents or spills, and waste disposal. Dimethyl sulfoxide and ethylene glycol are both classified as irritants, and Murashige and Skoog basal media contains irritants and oxidizing solids.

The amount of PVS2 needed depends on the number of shoot tips, number of accessions, and the chosen method of cryopreservation. Typically, 250 mL or 500 mL are prepared at a time. The following recipe makes 250 mL.

Prepare a vessel larger than the final volume. Use a stir bar and stir plate to combine the following ingredients: glycerol, ethylene glycol, sucrose, dimethyl sulfoxide, and Murashige and Skoog Basal Medium.

Glycerol, 30% (w/v): 75 g. Weight per volume is calculated as g/100 mL; therefore a 30% solution is equal to 30 g per 100 mL, or 75 g per 250 mL solution. Glycerol is a viscous liquid measured by weight, rather than volume. As the first ingredient, it may be weighed directly in the mixing vessel, or weighed separately.

Ethylene glycol, 15% (w/v): 33.7 mL. 15% is equal to 15 g per 100 mL or 37.5 g per 250 mL solution. Ethylene glycol comes as a liquid that may be weighed or measured by volume using a graduated cylinder or serological pipette. With a density of 1.113 g/cm3, the volume of ethylene glycol needed is 33.7 mL.

Sucrose, 0.4 M: 34.23 g. To prepare a 0.4 M solution, consider that the molar mass of sucrose is 342.3 g/mol; therefore a 0.4 M solution would require 136.92 g per 1 L, or 34.23 g per 250 mL solution.

Dimethyl sulfoxide, 15% (w/v): 34.1 mL. 15% is equal 37.5 g per 250 mL solution. Dimethyl sulfoxide, also called DMSO, comes as a liquid that may be weighed or measured by volume. With a density of 1.100 g/cm3, the volume of needed is 34.1 mL.

PhytoTech Labs Murashige and Skoog Basal Medium (M519), ½ strength: 0.55 g. Murashige and Skoog basal medium, also called MS, is a now commonly used formulation (with many variations) initially developed and published by Murashige and Skoog (1962). While MS salts and vitamins may be purchased and measured individually, a variety of chemical vendors carry pre-blended formulations that tend to simplify and speed up the media-making process. The mass needed to make a full-strength MS should be listed by the chemical vendor.

Add distilled water until the volume is slightly less than the full amount—in this case about 230 mL or so. Let stir until all ingredients are in solution and the media becomes clear. If the sucrose will not go into solution after about 10 minutes, more water may be needed. Pour the solution into an appropriately sized graduated cylinder and bring to full volume, 250 mL, with distilled water. Pour the solution back into the beaker and stir.

Make sure your pH meter is calibrated, then set it up near the stir plate. Place the probe in the stirring PVS2. Prior to adjustment, the solution will be slightly acidic, so a dilute potassium hydroxide (0.1 M recommended) will be needed to increase the pH to 5.8. Add one drop at a time and wait for a stable reading before adding more.

Sterilize the PVS2 using a vacuum-based filtration system. Choose a filtration unit, such as Millipore Stericups, with a pore size of 0.45 microns; smaller pore size would also be suitable for preventing contamination but may increase the probability of clogging. Pour the solution into the funnel and use a vacuum hose to pull the media through the membrane into the sterile chamber. Do not open the sterile chamber until the whole unit has been surfaced sterilized and placed in a sterile environment such as a laminar flow hood.

Once in a laminar flow hood, the vessel may be sealed, or the media may be aliquoted to smaller vessels that will be more convenient for regular use. Sterile 50 mL centrifuge tubes, test tubes, or similar vessels are appropriate. To prevent spillage, contamination, or desiccation, we recommend wrapping PVC sealing film where the cap meets the vessel. Apply labels to each tube, minimally indicating the contents, date, and hazard information.

While PVS2 can be stored at room temperature, refrigerated storage (3-5 oC) is used to increase shelf life, and pre-cool the solution for protocols that require cold application of PVS2. If the solution has not been used within 6 months, we recommend disposing of it as hazardous waste.

4. variations

Staff at NLGRP use at least two other variations of the recipe described in this chapter. One variant uses full-strength MS; for most crops tested, no noticeable difference in results has been observed between those processed with PVS2 (½ MS) and those processed with PVS2 (full-strength MS). Another variant sometimes used is half-strength PVS2, wherein the described recipe is altered by halving the amount of glycerol, ethylene glycol, and DMSO; at NLGRP, this is used in the procedure for cryopreserving grape (Vitis) shoot tips.

5. references

Murashige T, Skoog F. 1962. A revised medium for rapid growth and bio assays with tobacco tissue cultures. Physiologia Plantarum 15:473-497.

Nishizawa S, Sakai A, Amano Y, Matsuzawa T. 1993. Cryopreservation of asparagus (Asparagus officinalis L.) embryogenic suspension cells and subsequent plant regeneration by vitrification. Plant Science 91:67-73.

Sakai A, Hirai D, Niino T. 2008. Development of PVS-based vitrification and encapsulation–vitrification protocols. In: Reed BM (editors) Plant Cryopreservation: A Practical Guide. Springer, New York, NY.

Sakai A, Kobayashi S, Oiyama I. 1990. Cryopreservation of nucellar cells of navel orange (Citrus sinensis Osb. var. brasiliensis Tanaka) by vitrification. Plant Cell Reports 9:30-33.

6. Additional information

The PVS2 recipe is available to download here.

7. Acknowledgements

Citation: Chen KY, Bonnart RM, Volk GM. 2022. Preparing Plant Vitrification Solution 2. In: Volk GM (Eds.) Training in Plant Genetic Resources: Cryopreservation of Clonal Propagules. Fort Collins, Colorado: Colorado State University. Date accessed. Available from https://colostate.pressbooks.pub/clonalcryopreservation/chapter/pvs2/

This training module was made possible by:

Editors: Katheryn Chen, Gayle Volk

Content providers: Katheryn Chen, Remi Bonnart

Videographer: Emma Balunek

This project was funded by the USDA-ARS and by the USDA-NIFA Higher Education Challenge Program grant 2020-70003-30930.

USDA is an equal opportunity provider, employer, and lender. Mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture.